Industry news

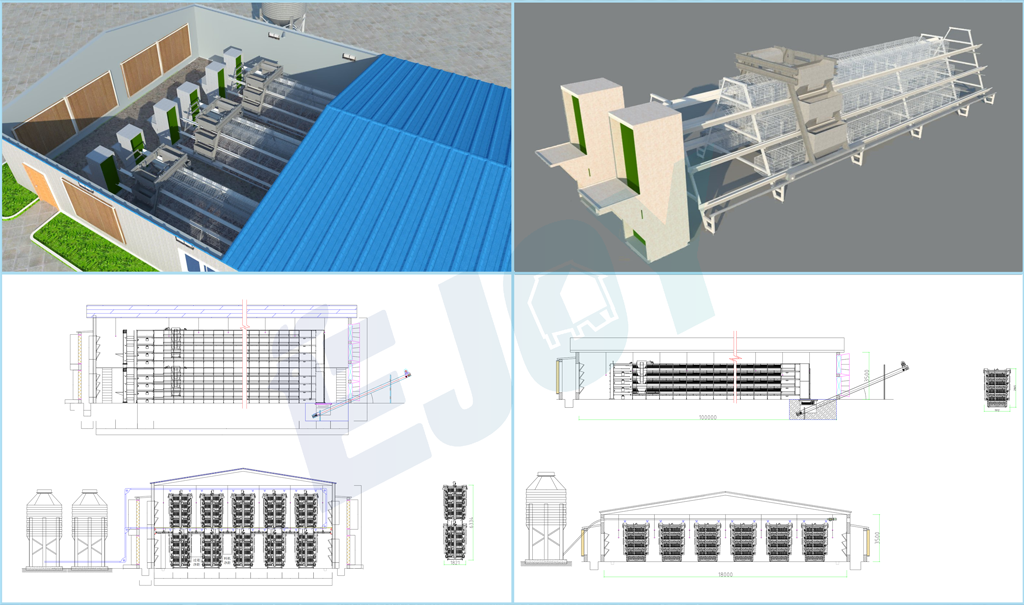

A-Frame vs H-Frame Layer Cages: Which One is Right for Your Poultry Farm?

Added:2025-09-25

The foundation of a successful and profitable layer farm is the cage system. The decision between A type layer cages and H type layer cages is critical, influencing everything from poultry health and management efficiency to your final return on investment. The best choice depends entirely on your farm's specific scale, goals, and budget.

This guide provides a comprehensive comparison to help you select the system that will drive your success.

Quick Comparison: A Type vs. H Type Cages

Feature | A-Type Chicken Cages | H-Type Chicken Cages |

Structure | Tiers are staggered. | Tiers are vertically stacked. |

Space Efficiency | Lower density. Ideal for 10k-25k birds. | High density. Ideal for 30k+ birds. |

Ventilation | Excellent natural airflow. | Requires controlled mechanical ventilation. |

Automation Level | Basic to semi-automated. | Fully automated (feeding, egg collection, manure cleaning). |

Initial Investment | Lower. | Higher, but offers lower operational costs. |

Applies to | Small/medium farms, hot climates, limited budget. | Large-scale, intensive farming operations. |

1. A Type Layer Cages: The Practical Choice

A type cages are a proven, reliable solution known for their simplicity and effectiveness.

▪ Optimal Scale: This system is the most cost-effective for operations with 10,000 to 25,000 birds.

▪ Advantage: Excellent Natural Ventilation.

The staggered design allows heat and ammonia to escape naturally, promoting bird health and reducing the need for complex environmental controls. This makes them ideal for warmer climates.

▪ Investment Outlook: The lower initial investment lowers the barrier to entry for new farmers or those with budget constraints. They are also easier to install in existing poultry houses.

2. H-Type Layer Cages: An Even More Efficient Choice

H-type cages are engineered for maximum productivity and labor savings in large-scale operations.

▪ Optimal Scale: This system is designed for large-scale operations, typically starting from 30,000 birds and extending to hundreds of thousands.

▪ Advantage: Total Automation. H-type cages are integrated with high-efficiency systems that significantly reduce labor:

※ Central Egg Collection: Minimizes egg breakage

※ Conveyor Belt Manure Removal: Ensure a clean environment

※ Advanced Climate Control: Ensures a more stable environment for poultry.

▪ Investment Outlook: Although upfront costs are higher, significant reductions in labor costs and higher output per square meter deliver a strong long-term return on investment (ROI) for large farms.

5 Key Decision-Making Factors

Answer these questions to find your best fit:

① What is your current and future flock size? (Most critical factor)

② What is your available capital budget?

③ What are your local labor costs and availability?

④ Are you building a new house or update an old one?

⑤ What is the primary climate in your region?

Conclusion

Choosing between A-frame and H-frame layer cages is not just about buying equipment — it’s about making a smart investment in your farm’s future. By following the key factors in this guide, you can select the system that supports efficient and sustainable poultry production.

As a professional poultry farming equipment manufacturer and farm solution provider, Ejoy is your trusted partner. If you are interested in our poultry farming equipment, please contact us today!