Industry news

Poultry House Lighting Management: Scientific Strategies for Optimal Performance

Added:2025-08-19

Introduction: Lighting as a Core Management Tool

Lighting in poultry farming is more than illumination; it shapes growth, production, and flock behavior. Chickens respond to spectrum, color temperature, and intensity differently from humans. Understanding these factors enables efficient management without additional feed or labor costs.

Why Scientific Lighting Management Matters

1. Enhanced Production Efficiency

✅ Boost egg production by 3–5% through optimal red-light stimulation

✅ Reduce feed waste by aligning light intensity with bird activity patterns

✅ Minimize stress and pecking via balanced light exposure

2. Long-Term Cost Savings

✅ Energy-efficient LED systems reduce electricity consumption

✅ Proper maintenance extends lamp lifespan and reduces replacements

✅ Fewer health issues

3. Compliance with Global Standards

✅ FAO/AVIAGEN guidelines on light intensity and duration

✅ EU regulations on animal welfare through lighting optimization

Key Lighting Management Principles

1. Color Temperature: Warm vs. Cool Light

Lamp Code | Color Temp | Best For |

830 | 3000K | Production phase (layer) – stimulates reproduction |

840 | 4000K | Rearing phase (pullets) – balances growth and behavior |

860 | 6000K | Broilers – promotes feeding and activity |

▪ Recommendation: Switch from 840 to 830 at transfer to lay — this increases red-light exposure even if lux stays the same.

2. Lux & Spectrum Balance

Phase | Lux Range | Key Goal |

Rearing (0–18 wks) | 10–20 lux | Control maturity and reduce stress |

Production (19 wks+) | 20–30 lux | Stimulate ovulation and egg production |

Broiler Rearing | 20–30 lux | Promote feeding and uniform growth |

▪ Critical Insight: Lux meters alone cannot distinguish between wavelengths. A 6000K lamp with high lux may appear bright to humans but lack red-light stimulation for hens.

3. Light Spectrum: Red vs. Blue

✅ Red/Orange Light (600–700 nm):

Penetrates skull and activates brain photoreceptors, triggering hormonal changes for ovulation and egg production.

✅ Blue/Green Light (400–500 nm):

Enhances vision and activity, ideal for broiler rearing and pullet development

▪ Scientific Fact: Chickens have deep-brain photoreceptors. Red light reaches these cells more effectively than blue or white light.

Step-by-Step Lighting Implementation

Step 1: Assess Your Farm's Needs

✅ Determine bird type (layers/broilers) and growth stage

✅ Check current lighting setup (age, efficiency, coverage)

✅ Identify energy and cost constraints

Step 2: Select Appropriate Lamps

✅ Use 830 (3000K) for production

✅ Use 840 (4000K) for rearing

✅ Avoid mixing lamp types to prevent stress

Step 3: Install and Test

✅ Ensure even light distribution across the house

✅ Test lux levels and spectrum balance using a spectral meter

✅ Adjust height and angle for optimal coverage

Step 4: Monitor and Maintain

✅ Clean lamps and fixtures monthly to prevent dust buildup

✅ Replace damaged or inefficient bulbs promptly

✅ Log performance data (egg production, feed conversion)

Conclusion: Lighting for Sustainable Growth

Lighting is not just infrastructure — it’s a strategic tool for improving productivity, reducing costs, and ensuring bird welfare. By following this guide, farms across Latin America, Southeast Asia, Europe, and Africa can achieve consistent, efficient, and profitable poultry production.

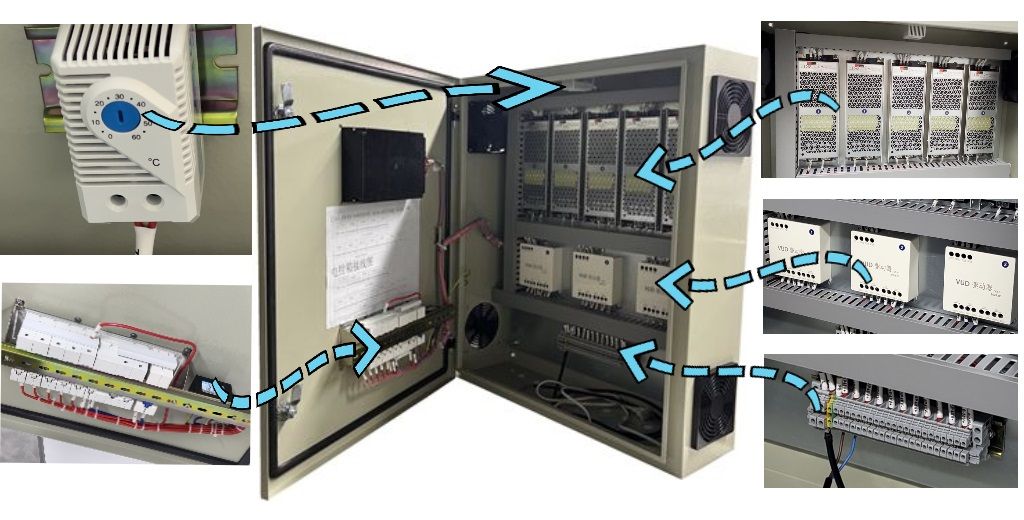

Ejoy Poultry Lighting delivers precise color temperatures and stable, dimmable spectra to optimize laying, growth, and flock welfare. With 3000K for layers and 6000K for broilers, our IP65-rated fixtures withstand demanding farms while providing up to 50% energy savings through intelligent, flicker-free dimming and surge protection. Easy setup via a multilingual touchscreen controller, wide voltage input, and durable build make Ejoy a smart, sustainable choice for modern poultry farming.