Industry news

EC Fan Efficiency and Adaptive Optimization for Southeast Asia

Added:2025-11-05

In environmental control systems for large-scale farms, fan energy efficiency is a key factor affecting operational costs. Typically, fan electricity consumption accounts for approximately 40% of a farm's total energy usage. Reducing fan operating costs is therefore a primary concern for farm owners.

This issue is particularly pronounced in the Southeast Asian market. The hot and humid climate demands higher indoor air speeds, leading to a greater number of fans being installed. Consistently high temperatures require fans to operate continuously for extended periods. Combined with generally higher electricity prices in the region, reducing fan energy consumption is especially significant—from the perspectives of quantity, runtime, and cost per unit of electricity.

For a long time, industry understanding of fan performance has primarily focused on motor efficiency, with the belief that using a higher-efficiency motor alone can lead to substantial energy savings. Indeed, EC motors typically achieve IE4–IE5 efficiency ratings, while AC motors commonly fall within IE2–IE3. For large-sized (over 50 inches) direct-drive fans using 700 RPM motors, there is indeed an approximate 10% efficiency difference between the two.

However, overall fan energy efficiency depends not only on the motor itself but more critically on the aerodynamic design of the blades and how well the entire system is matched and integrated.

This article will analyze EC fan efficiency, combined with EJOY's test data from Malaysia, to explore why the overall aerodynamic efficiency of the complete fan unit often matters more than motor efficiency alone, and to explain how EJOY achieves adaptive optimization to ensure stable and efficient fan performance under the complex operating conditions found in Southeast Asia.

I. Analysis of EC Fan Efficiency

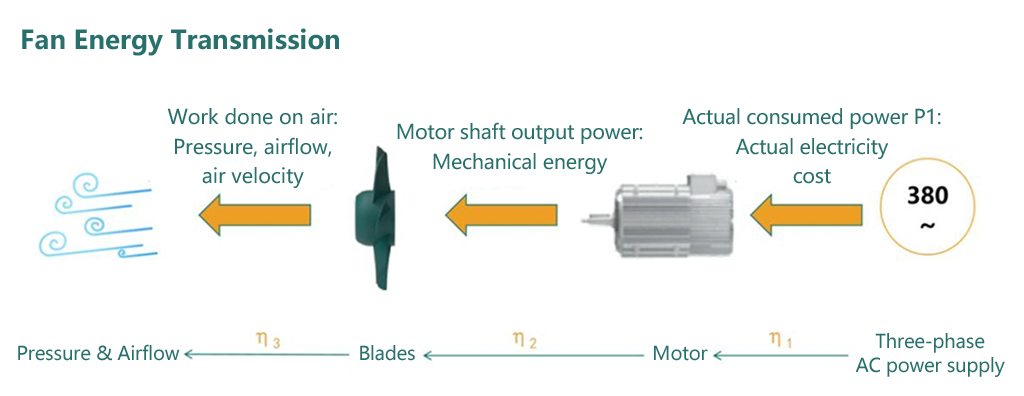

From the perspective of energy conversion, fan operation can be broken down into three key stages:

1. Electrical power from the grid is converted into mechanical energy by the motor (motor efficiency η₁).

2. This mechanical energy is transmitted to the blades via the transmission assembly (energy transfer rate η₂).

3. Finally, the blades perform work on the air, generating airflow and static pressure (aerodynamic efficiency η₃).

Let's first examine η₂ — transmission efficiency.

Traditional belt-driven fans suffer from friction and slippage losses in the belt-pulley system, resulting in approximately 5% energy loss. Therefore, belt transmission efficiency typically reaches around 95%. In contrast, modern EC fans commonly employ a direct-drive configuration, eliminating mechanical transmission losses. As such, transmission efficiency can be considered effectively 100%, making this factor negligible in overall efficiency calculations.

Next, consider η₁ — motor efficiency.

Take, for example, a 50 Hz, 8-pole, 1.8 kW motor:

- An AC induction motor at IE3 efficiency level achieves approximately 81% efficiency.

- A comparable EC motor reaches about 90% efficiency.

This means that simply upgrading to an EC motor can improve motor-stage efficiency by nearly 9 percentage points.

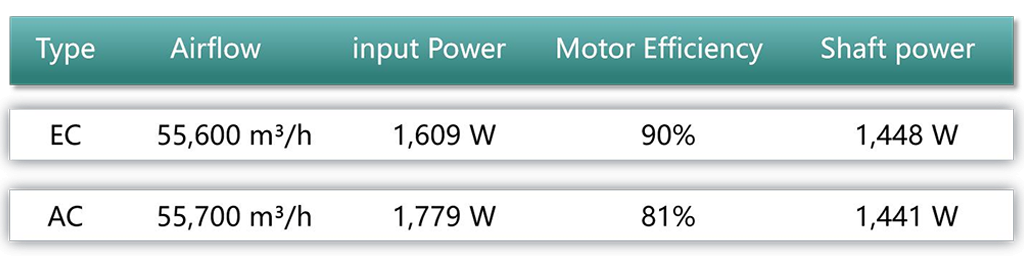

This advantage has been confirmed through EJOY's standardized performance testing under controlled conditions (25 Pa static pressure):

- EC Fan Configuration: Airflow: 55,600 m³/h, Input Power: 1,609 W

- AC Fan Configuration: Airflow: 55,700 m³/h, Input Power: 1,779 W

The data shows that the EC fan delivers nearly identical airflow while consuming 270 watts less power — a reduction of approximately 15.2% in energy consumption at the same operating point.

Since the only difference between the two fans is the motor, while all other components, test conditions, and airflow results remain consistent, it is reasonable to assume that aerodynamic efficiency (η₃) is nearly identical.

Experimental data confirms that shaft power output is almost equal:

- EC Fan: 1,609 W × 90% ≈ 1,448 W

- AC Fan: 1,779 W × 81% ≈ 1,441 W

The difference in shaft power (approximately 7 W) is entirely attributable to the 9% difference in motor efficiency, resulting in about 170 W of input power savings. This demonstrates that upgrading from IE2/IE3 AC motors to IE4/IE5 EC motors does deliver measurable energy savings — but the improvement is primarily limited to the motor efficiency stage.

However, when comparing EC fans with similar efficiency ratings but from different manufacturers, the difference in motor efficiency (η₁) becomes negligible. In such cases, the key factor determining overall fan performance shifts to aerodynamic efficiency (η₃), which depends on blade design and system integration.

This stage involves advanced airfoil optimization and is a core focus of EJOY's engineering development for high-performance ventilation systems.

II. Blade Design and Aerodynamic Efficiency

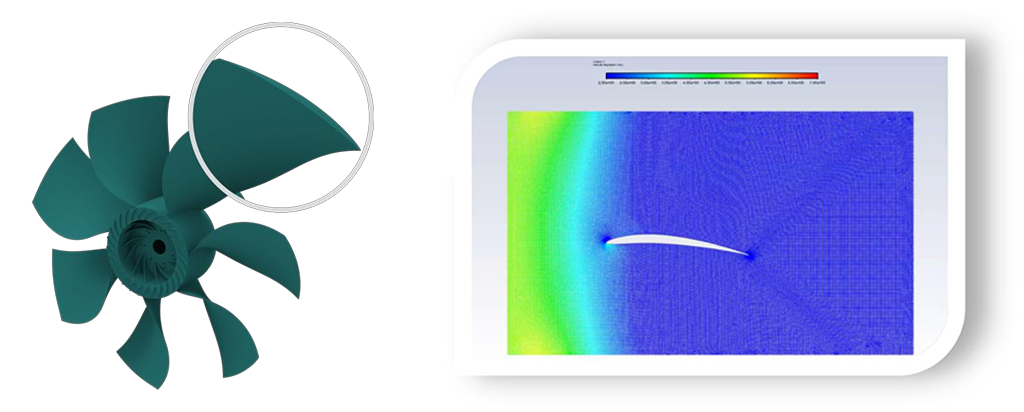

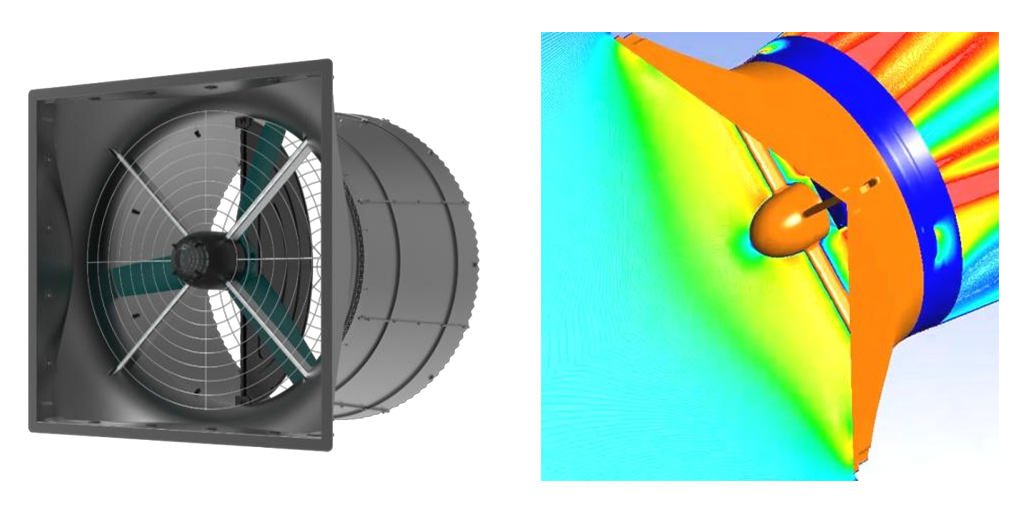

1. Airfoil Blade Design

EJOY's modern high-efficiency fans commonly use airfoil-shaped blades instead of traditional flat-blade designs. Airfoil blades resemble aircraft wings and generate high lift-to-drag ratios at both low and high speeds. When airflow passes over them, the boundary layer adheres closely, minimizing turbulence and pressure loss. This paper focuses on full-speed performance under standard operating conditions.

EJOY's dedicated fluid dynamics team conducts theoretical calculations and computational simulations during blade development. Based on specific operating requirements, an appropriate airfoil profile is selected, followed by precise adjustments to installation angle, chord length, and pitch distribution to optimize performance across the entire speed range.

The initial blade model is established based on theoretical calculations of parameters such as chord length, installation angle, and pitch distribution. However, this initial design alone is insufficient. Further optimization requires computational fluid dynamics (CFD) simulation to evaluate airflow performance and power consumption under various rotational speeds and pressure conditions.

During the simulation process, pressure distribution across the blade surface is analyzed to identify and optimize aerodynamic losses. Each iteration involves computational modeling and performance validation to progressively approach the optimal solution. Through multiple rounds of refinement, EJOY develops blade designs that balance efficiency, stability, and reliability.

This systematic engineering process enables EJOY's high-performance fans to achieve superior aerodynamic efficiency in real-world operation.

2. Streamlined Casing Optimization

In addition to blade design, the casing and tip region also significantly influence fan efficiency. EJOY optimizes the streamlined casing shape and controls the clearance between the blade tip and casing to effectively reduce leakage losses, ensuring high-efficiency operation even at high airflow output.

A smooth inlet section promotes laminar flow transition, minimizing flow separation at the entrance and improving overall aerodynamic performance.

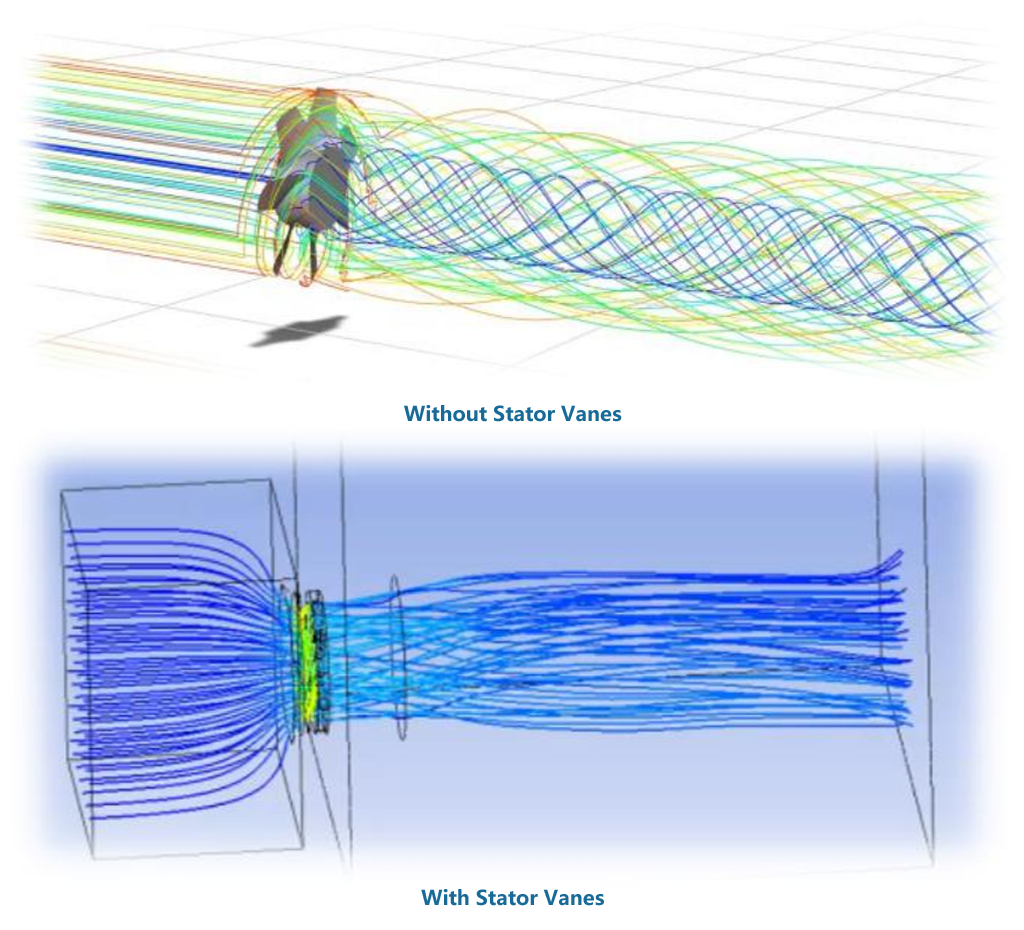

3. Stator Vanes and Anti-Swirl Technology

In certain EJOY product models, stator vanes are incorporated into the fan design. These stationary blades are positioned downstream of the rotating blades to redirect the swirling airflow generated by rotation. By re-aligning the vortex flow, stator vanes convert kinetic energy more efficiently into static pressure, thereby enhancing system efficiency and reducing turbulence losses. This technology helps improve total pressure recovery and contributes to higher overall fan performance, especially in applications requiring stable, high-pressure ventilation.

The combination of airfoil blades, streamlined casing design, and stator vanes significantly improves airflow organization and pressure recovery. This integrated approach reduces turbulence and swirl losses, resulting in higher overall aerodynamic efficiency.

Even under identical motor specifications, EJOY's optimized design enables our fans to achieve superior energy performance compared to conventional models.

Case Study: EJOY's Testing in Malaysia

A real-world test in Malaysia compared two identical poultry houses. One house was equipped with 12 units of a well-known brand's 57-inch EC fan (motor efficiency 91%), while the other used 12 units of EJOY's 57-inch EC fan (motor efficiency 90%).

Measurement results showed that the average current draw per fan for the well-known brand was 3.86A, while EJOY fans averaged only 2.94A. Assuming similar voltage and power factor, this indicates an approximate 24% reduction in power consumption per fan for EJOY models.

This case clearly demonstrates that the impact of blade aerodynamic efficiency can far exceed that of motor efficiency alone. Even hypothetically replacing the 90% efficiency EC motors in EJOY fans with standard IE3 AC motors (approx. 81% efficiency), calculations show our overall system would still consume about 14% less energy than the well-known brand's EC fans.

III. Fan Stability and Adaptability for Southeast Asian Conditions

In the Southeast Asian market, fans must not only be energy-efficient but also highly reliable. The region's hot and humid climate, frequent thunderstorms, and unstable power supply make voltage fluctuations and outages common. A sudden ventilation failure can quickly lead to animal stress or even significant economic losses.

To address these challenges, EJOY's EC fan designs have been specifically optimized for tropical operating conditions — ensuring stable performance under harsh environmental and electrical conditions.

Compared to traditional AC motors, EC motors feature advanced structural materials and integrated drive and control circuitry. This enables them to convert AC input into DC, then invert it to drive the motor, while also providing intelligent communication and protection functions.

1. Intelligent Protection System: Ensuring Continuous Operation

EJOY's EC fans are equipped with built-in multi-level protection mechanisms, including overvoltage, undervoltage, phase loss, overcurrent, stall, and overload protection.

Unlike conventional motors that simply shut down during faults, our smart systems adopt intelligent control logic: as long as the motor can operate, it will maintain airflow at reduced speed to minimize the risk of oxygen deficiency inside the barn.

For example, consider EJOY's 50-inch fan model powered by three-phase 380V supply. Its normal operating voltage range is 342V–506V. When voltage drops below the lower limit (e.g., to 181V), instead of stopping immediately, the motor automatically reduces speed to maintain ventilation. At this low voltage, it can still run at 495 RPM, delivering approximately 70% of full-speed airflow.

This ensures continuous cooling and air exchange, even during temporary grid instability.

2. Communication Loss Emergency Mode

In the event of communication failure between the central controller and individual fans, EJOY's system switches to emergency mode. Fans continue running at a preset minimum speed to ensure basic ventilation, preventing complete shutdown during system faults.

This feature enhances reliability in remote or poorly maintained farms where network interruptions may occur frequently.

In hot and densely populated farms in Southeast Asia, a sudden fan shutdown can rapidly increase indoor temperature, leading to animal stress or even mortality. To address this, EJOY's EC fans are equipped with multiple emergency operating modes.

When communication signals are lost, our system can be configured to either:

- Maintain the last commanded speed, or

- Switch to a fixed safe speed

This ensures continued ventilation even if faults occur during nighttime operations or when on-site personnel cannot respond promptly — significantly reducing the risk of severe consequences.

3. Lightning Protection and High Ingress Protection Rating

Lightning strikes and power surges are common in Southeast Asia. Some imported brands have suffered widespread damage due to inadequate lightning protection design.

EJOY's EC motors have passed a 6 kV lightning surge test (the highest standard in laboratory testing), combined with standardized grounding solutions, significantly reducing the risk of lightning-induced failures.

Our motor's ingress protection rating reaches IP66, enabling long-term operation in high-humidity environments. It has successfully passed a 7-day continuous immersion test and can withstand direct high-pressure water jet cleaning — making it ideal for frequent washing in livestock facilities.

Through these region-specific optimizations, EJOY's high-efficiency fans are not only more energy-efficient but also designed for reliable performance under complex local conditions: unstable power grids, extreme climates, and high load demands. This enables our customers to reduce operational risks and minimize losses, delivering a truly locally adapted ventilation solution.

Conclusion

By analyzing the three key efficiency components — motor efficiency (η₁), transmission efficiency (η₂), and aerodynamic efficiency (η₃) — it becomes clear that while improving motor efficiency does contribute to energy savings, the difference between similarly rated motors is limited.

The true determinant of overall fan efficiency lies in blade aerodynamic design and system integration.

EJOY leverages a complete forward-developed R&D framework to achieve significant energy consumption advantages in fans under identical operating conditions through integrated optimization of airfoil blades, streamlined casings, and stator vane technology.

Our testing in Malaysia confirms this: despite a marginally lower motor efficiency, EJOY's overall system achieved 24% energy savings — clearly demonstrating the critical importance of aerodynamic efficiency.

However, efficiency is just the first step. In the Southeast Asian market, stability and reliability are the real challenges.

From automatic speed reduction under undervoltage, to emergency operation during communication loss, and through rigorous 6 kV lightning surge testing and IP66 protection rating, EJOY's fans are engineered to operate reliably under extreme conditions — including voltage fluctuations, frequent thunderstorms, and high humidity with heavy loads.

This holistic design philosophy ensures long-term performance and peace of mind for farm operators in demanding tropical environments.

It can be said that high-efficiency aerodynamic design, intelligent EC drive technology, and regional adaptation optimization constitute the three core competitive advantages of EJOY's high-performance fans. This integrated approach not only helps reduce energy costs for our customers but also ensures safe operation and animal welfare in livestock facilities, providing a truly "energy-saving, worry-free, and reliable" ventilation solution for the Southeast Asian poultry industry.